horstOS ist eine durchgängige Software, die Physical AI für industrielle Automatisierung nutzbar macht und Planung, Umsetzung sowie Betrieb ohne Medienbrüche vereint.

Übersicht unserer Industrieroboter

HORST600

HORST1000

HORST1000 G2

HORST1500 G2

4 Minuten zu lesen

Benjamin Brumm

:

Apr 7, 2025 7:30:00 AM

Benjamin Brumm

:

Apr 7, 2025 7:30:00 AM

Ob in der medizinischen Diagnostik, in Forschungs- oder in Qualitätssicherungslaboren: Die Nachfrage nach Probenbearbeitung sowie die Anforderungen an Präzision und Geschwindigkeit steigen kontinuierlich stark an. Wenn manuelle Routinearbeiten wie Pipettieren oder Sortieren viel Zeit kosten, führt das jedoch zu Belastung und Monotonie unter Labormitarbeitern. Es hemmt zusätzlich die mögliche Produktivität von Laboren. In diesem Artikel erklären wir deshalb, welche typischen Tätigkeiten Roboter in Laboren bereits heute automatisieren können – und welche konkreten Vorteile dadurch entstehen.

1. Probenvorbereitung und Pipettieren

1. Probenvorbereitung und Pipettieren Die Probenvorbereitung gehört zu den arbeits- und zeitintensivsten Tätigkeiten im Labor. Das manuelle Pipettieren ist nicht nur fehleranfällig, sondern für Mitarbeitende auch körperlich belastend. Zudem kostet es viel Konzentration, stets die richtige Pipettier-Menge zu treffen und Kontaminationen zu vermeiden.

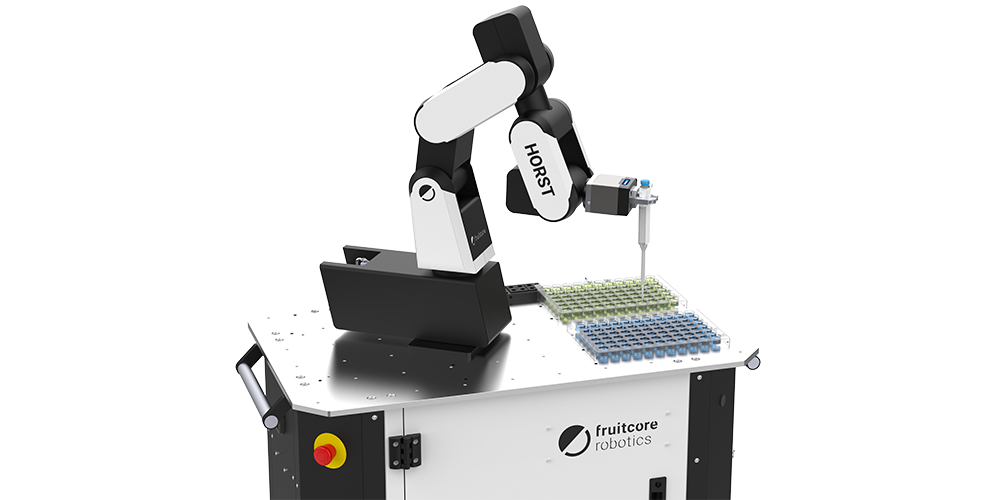

6-Achs-Industrieroboter, wozu zum Beispiel HORST Robotersysteme zählen, lassen sich mit sensiblen und labortauglichen Greifsystemen ausstatten, um Reagenzien hochpräzise zu dosieren. Mit einer entsprechend ausgerüsteten Software lässt sich das Pipettier-Setup dabei intuitiv grafisch festlegen und zügig und einfach an neue Methoden oder Protokolle anpassen.

2. Probenlogistik und Sortierung

2. Probenlogistik und Sortierung Gerade in der täglichen Routine klinischer Labore oder Dienstleistungslabore sammeln sich Probenröhrchen in großer Zahl an, müssen gescannt, verifiziert und auf verschiedene Analysegeräte verteilt werden. Auch die Archivierung – zum Beispiel in Kühlschränken oder Tiefkühlsystemen – bindet Kapazitäten.

Mehrere Laborverbünde in Europa haben bereits Roboterlösungen zur Probenlogistik im Einsatz, die stündlich mehrere Hundert Röhrchen sortieren. Die Roboter können dabei auf einer mobilen Plattform stationiert werden, um sie am Ort der Beprobung zu positionieren und bei Bedarf schnell umzustellen – etwa von der Sortierung zur Maschinenbestückung.

3. Beschickung von Analysegeräten

3. Beschickung von Analysegeräten Geräte wie Zentrifugen, PCR-Systeme, Spektrometer oder chromatografische Analyseeinheiten laufen zwar teilautomatisiert, benötigen aber meist eine manuelle Zu- und Abführung. Dadurch bleiben teure Geräte zwischen den Bearbeitungsschritten teilweise ungenutzt.

In einem Diagnostikzentrum kann ein Roboter mit Doppelgreifer rund um die Uhr Proben aus Racks entnehmen, in ein Analysegerät einführen und anschließend das verarbeitete Röhrchen zur Archivierung in ein separates Tray ablegen. Das Laborpersonal kontrolliert nur noch die Resultate, statt repetitive Ladevorgänge auszuführen.

4. Probenarchivierung und Lagerverwaltung

4. Probenarchivierung und Lagerverwaltung Je nach Branche werden Proben und Rückstellmuster teils Monate oder Jahre lang gelagert. Das Sortieren in Lagerracks oder das Auffinden einzelner Proben zur späteren Nachanalyse bedeutet häufig einen immensen Verwaltungsaufwand.

Häufig realisieren Labore eine Kombination aus Roboter-Anwendung und automatischem Lagersystem (z.B. Tiefkühl- oder Kühlschrankmodul). Hier helfen Roboter-Softwares, die bei der Schnittstellen-Kommunikation offen für viele Systeme sind, damit jede Bewegung dokumentiert werden kann. Innovative Software-Lösungen wie horstOS nutzen dabei auch die Vorzüge von Künstlicher Intelligenz und des Internet of Things. So lässt sich einstellen, dass die Software proaktiv darüber informiert, wenn z.B. bestimmte Proben an die Oberfläche geholt werden sollen.

5. Dokumentation und Qualitätskontrolle

5. Dokumentation und Qualitätskontrolle In vielen Laboren wird noch manuell dokumentiert – beispielsweise bei der Kontrolle von Füllständen, Pipettenkalibrierungen oder Protokollierung von Versuchsergebnissen. Das bindet Personal und ist fehleranfällig. Darum ist eine verlässliche Rückverfolgbarkeit, die sogenannte traceability, ein so wichtiges Thema für Laborbetriebe und betrifft im Grunde alle Bearbeitungsschritte.

Ein Industrieroboter mit integrierter Kamera fährt Probenstationen ab, filmt/scannt Füllstände oder Farbveränderungen und überträgt die Messwerte automatisiert an die Labor-Software. Für die Absicherung kann eine zentrale Steuerung sorgen, die bei Unstimmigkeiten den Vorgang stoppt und gleichzeitig das Personal alarmiert – ganz ohne Zeitverlust.

Diese fünf Beispiele zeigen, dass sich bereits mit der Automatisierung einzelner Laborprozesse deutliche Effizienz-, Qualitäts- und Zeitgewinne erzielen lassen. Wer sich für einen modularen Ansatz entscheidet – beispielsweise auf Basis des leicht zu bedienenden Industrieroboters HORST – kann sogar klein anfangen und Schritt für Schritt erweitern. So profitieren Sie sofort von kürzeren Durchlaufzeiten und geringerer Fehlerquote, ohne Zeit und Geld in Sonderanlagen investieren zu müssen.

Wer jetzt in eine Robotik-Lösung investiert, macht sein Labor fit für die stetig steigenden Anforderungen an Tempo, Qualität und Wirtschaftlichkeit – und schafft ideale Bedingungen, um Fachkräfte zu entlasten und die Ergebnisqualität zu steigern.

Gerne beraten wir Sie persönlich, welcher Prozess in Ihrem Labor das größte Automatisierungspotenzial bietet. So starten Sie in kürzester Zeit, Ihre Proben, Geräte und Dokumentationen robotergestützt zu automatisieren – Schritt für Schritt, individuell an Ihre Anforderungen angepasst.