horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

5 min read

Benjamin Brumm

:

May 9, 2025 12:44:18 PM

Benjamin Brumm

:

May 9, 2025 12:44:18 PM

Whether in medical diagnostics, research or quality assurance laboratories, the demand for sample processing and the requirements for precision and speed are constantly increasing. However, when manual routine tasks such as pipetting or sorting take up a lot of time, this leads to stress and monotony among laboratory staff. It also hinders the potential productivity of laboratories. In this article, we explain which typical tasks robots can already automate in laboratories today—and what specific advantages this brings.

1. Sample preparation and pipetting

1. Sample preparation and pipettingSample preparation is one of the most labor-intensive and time-consuming tasks in the laboratory. Manual pipetting is not only prone to errors, but also physically demanding for employees. In addition, it requires a great deal of concentration to always pipette the correct amount and avoid contamination.

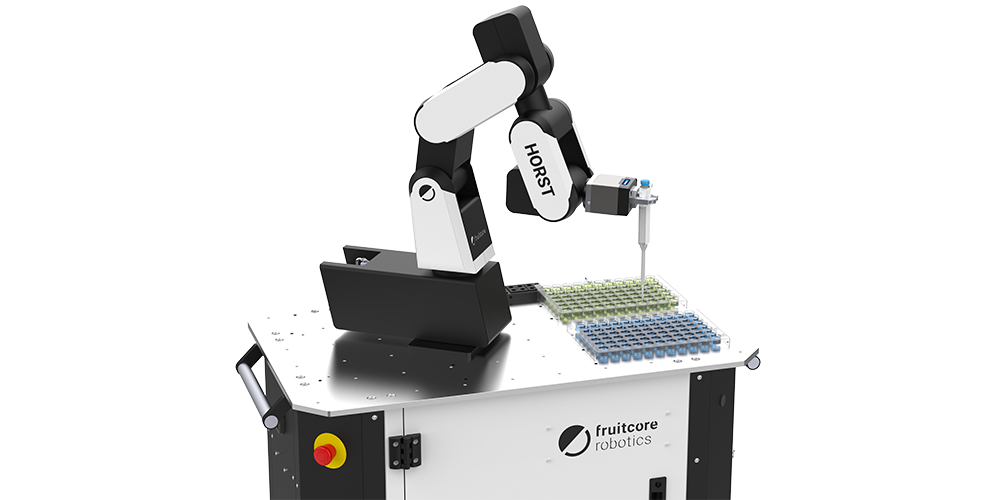

6-axis industrial robots, such as HORST robot systems, can be equipped with sensitive gripping systems suitable for laboratory use to dose reagents with high precision. With appropriately equipped software, the pipetting setup can be intuitively defined graphically and quickly and easily adapted to new methods or protocols.

2. Sample logistics and sorting

2. Sample logistics and sorting In the daily routine of clinical laboratories or service laboratories in particular, large numbers of sample tubes accumulate, which must be scanned, verified, and distributed to various analysis devices. Archiving—for example, in refrigerators or deep-freeze systems—also ties up capacity.

Several laboratory networks in Europe are already using robotic solutions for sample logistics that sort several hundred tubes per hour. The robots can be stationed on a mobile platform so that they can be positioned at the sampling location and quickly moved as needed—for example, from sorting to machine loading.

3. Feeding analysis devices

3. Feeding analysis devices Devices such as centrifuges, PCR systems, spectrometers, and chromatographic analysis units are semi-automated, but usually require manual feeding and removal. As a result, expensive equipment remains partially unused between processing steps.

In a diagnostic center, a robot with dual grippers can remove samples from racks around the clock, insert them into an analysis device, and then place the processed tubes in a separate tray for archiving. Laboratory staff only need to check the results instead of performing repetitive loading tasks.

4. Sample archiving and warehouse management

4. Sample archiving and warehouse management Depending on the industry, samples and reference samples are sometimes stored for months or even years. Sorting them into storage racks or locating individual samples for later analysis often involves a huge amount of administrative work.

Laboratories often implement a combination of robot applications and automatic storage systems (e.g., deep-freeze or refrigerator modules). Robot software that is open to many systems for interface communication helps here, so that every movement can be documented. Innovative software solutions such as horstOS also leverage the advantages of artificial intelligence and the Internet of Things. For example, the software can be configured to proactively notify users when certain samples need to be brought to the surface.

5. Documentation and quality control

5. Documentation and quality control Many laboratories still use manual documentation—for example, when checking fill levels, calibrating pipettes, or recording test results. This ties up staff and is prone to errors. That is why reliable traceability is such an important issue for laboratory operations and basically affects all processing steps.

An industrial robot with an integrated camera travels between sampling stations, films/scans fill levels or color changes, and automatically transmits the measured values to the laboratory software. A central control system can be used for safety purposes, stopping the process in the event of discrepancies and alerting personnel at the same time – without any loss of time.

These five examples show that significant gains in efficiency, quality, and time can be achieved simply by automating individual laboratory processes. Those who opt for a modular approach—based, for example, on the easy-to-use HORST industrial robot—can even start small and expand step by step. This allows you to benefit immediately from shorter throughput times and lower error rates without having to invest time and money in special systems.

Investing in a robotics solution now will make your laboratory fit for the ever-increasing demands on speed, quality, and cost-effectiveness—and create ideal conditions for reducing the workload on skilled personnel and improving the quality of results.

We would be happy to advise you personally on which process in your laboratory offers the greatest potential for automation. This will enable you to start automating your samples, devices, and documentation with robot support in no time at all—step by step, tailored to your individual requirements.