horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

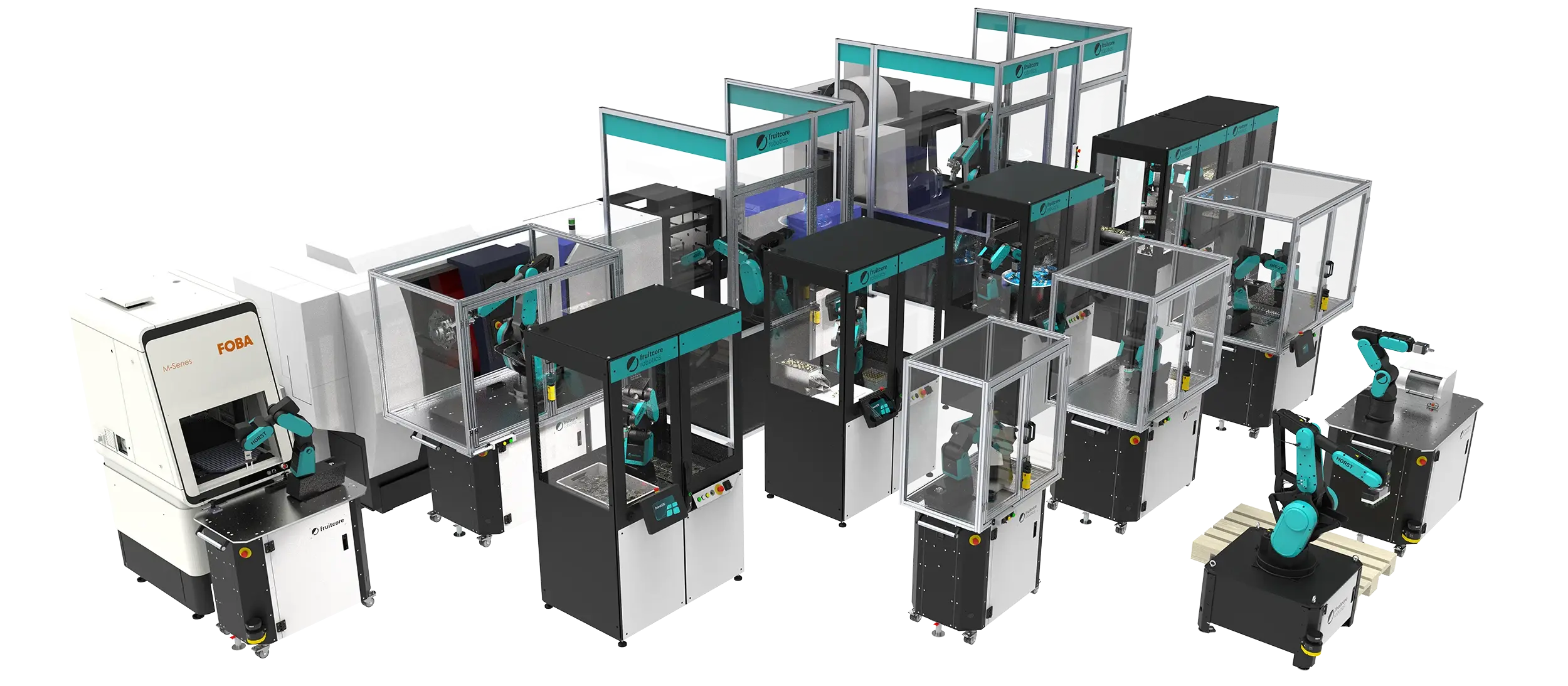

Our robotic solutions make automation easier, faster and more economical than ever before. Standardized, CE-certified systems that are ready for immediate use and can be seamlessly integrated into any production process - without the need for external integrators or long project phases.

No experts needed. Start intuitively and without programming knowledge.

Robots, software, control and service - perfectly coordinated. Made in Germany.

Plug & Produce instead of a project marathon - simply ready to go quickly, without detours.

Efficiency that pays off - investment amortized in record time.

This demonstration is not a classic industrial application, but shows the potential of modern physical AI. An industrial robot is controlled by voice, interprets instructions autonomously and converts them directly into physical actions. The art is the example - the added value lies in increasing efficiency and simplifying human-machine interaction in industry.

This solution makes robotics easily accessible. Learners work directly with a real industrial robot and gain practical experience - without any prior programming knowledge. The integrated AI Copilot acts as an intelligent supervisor, accompanying the learning process and increasing learning success in the long term.

Our robotic solutions combine everything that successful automation needs - from a single source and made in Germany.

Robots, software, controllers and accessories are fully developed in-house and perfectly coordinated.

No interface problems. No waiting times. No dependencies.

Set up in minutes, intuitively controllable.

Reach 600-1500 mm, load capacity up to 16 kg.

Proven peripherals directly from fruitcore robotics. Turnkey solutions available via certified partners.

Setting up, programming and controlling complete applications - graphically, quickly, consistently.

Direct line to support, certified partners worldwide, e-learning and training for users.

![]()

SCHERDEL Marienberg, a global automotive supplier with 6,800 employees and 45 production sites worldwide, shows how a robotic solution can be used to easily automate complex processes in the shortest possible time. A practical example that proves that simple automation is not a vision of the future, but reality.