6 min read

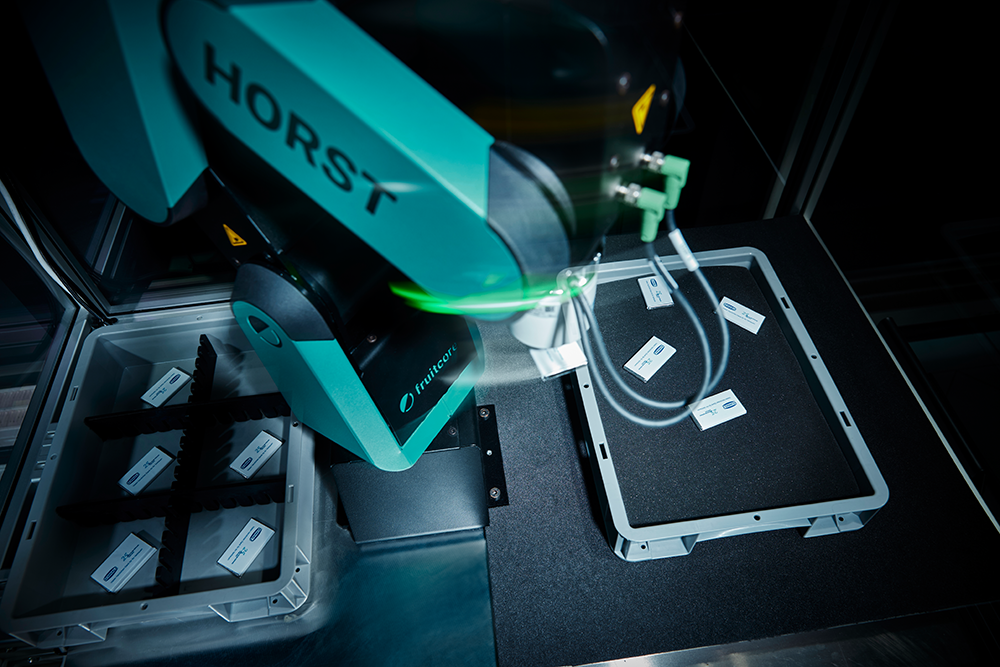

Robot-assisted quality control in diagnostics laboratories: a practical report

A medium-sized medical diagnostics laboratory in southern Germany was faced with serious challenges. Particularly at...

With low-maintenance robots, an intelligent, fully integrated robot operating system and a comprehensive ecosystem, your automation will be up and running immediately – up to 70% faster operationally and with about 85% less planning effort.

Our robotic systems are equipped with a unique, maintenance-free gear technology and extremely durable spherical bearings – for reliable, long-term operation without failures. Precise stepper motors ensure that HORST works efficiently and cost-effectively.

Up to 75% faster to deploy: With AI-driven software and real-time simulations, we significantly reduce your programming and commissioning effort compared to conventional solutions.

Up to 85% faster than usual: We save you a large part of the project planning time with preconfigured automation modules and plug-and-play components. Our modules and components can be seamlessly integrated into the robot and controlled via a single point of control without an additional PLC.

On average 50% lower than for other robots: The innovative, low- maintenance drive train of our robots halves your main tenance costs. In the long term, you save costs and produce efficiently without maintenance interruptions.

Around 95% lower than the market average: An integrated AI assistant helps you immediately with questions about errors and supports you in use and optimization. You can use an IIoT platform to create backups and access predictive maintenance and remote support.

A few hours instead of many days of training: Our intuitive software interface lets you learn how to use the robot in just a few hours via a digital learning platform. This reduces training costs by around 70 % compared to other manufacturers.

We take an integrated, holistic approach to the success of your automation project: robots, operating systems, complete solutions and service on a par with you – at fruitcore robotics, everything comes from a single source.

With just a few clicks, you can find the right automation for your project – customized and with transparent costs.

Whether you want to develop automation solutions together with us as an additional partner or need support in your region: you will find the right information here.

Expand the offering for your customers with solutions that use our robots and automation modules. We adapt to you!

Become a partner

Our easy-to-operate robot systems will make your processes more efficient in no time at all. We provide the right solution for your ideas.

Find a partner

Save valuable production time and avoid bottlenecks: Our solutions for the automated loading and unloading of your machine tools and production machines ensure smooth processes without interruptions: Increase your output and free up your employees' time for more demanding tasks.

Learn more about Machine Tending

Optimize your production processes with our flexible solution for separating, feeding, and discharging. Reliable and precise provision and positioning of workpieces are essential for efficient further processing. Use our flexible solution to sort a wide variety of parts quickly and without intervention.

Learn more about Part Separation

Ensure consistently high quality and minimize sources of error: inspect your components automatically – quickly and without manual intervention. This way, you reduce scrap, produce more sustainably and increase process reliability. Quickly adaptable to changing requirements at any time.

Learn more about Quality Inspection

Robert Meißner / Senior Expert Manufacturing Technologies, Research & Development at fischer group

Frank Reinauer / Senior Director Division Implants at Karl Leibinger Medizintechnik GmbH & Co. KG

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

Lorenz Geyer / Managing Director Eugen Geyer GmbH

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

Thomas Sehling / Operational Excellence Manager at WEBER-HYDRAULIK GmbH

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

Beat Glauser / CTO MBV AG

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

Siegmar von Detten / Computer science teacher at Zeppelin Gewerbeschule Konstanz

Daniel Weerts / Research assistant, Institute for Technology and Education (ITB), Bremen

Andreas Beck / Design technician for test equipment and fixture construction at the Villingen-Schwenningen plant

We provide you with all the building blocks for economical, flexible and efficient automation: developed and manufactured in Germany. Automation should not be a closed book for you, but should be quick, cost-efficient and easy to use. Our promise: The best return on investment – through durable technology, intuitive AI-supported software and ready-to-use automation modules.

Jun 27, 2025 by Benjamin Brumm

A medium-sized medical diagnostics laboratory in southern Germany was faced with serious challenges. Particularly at...

May 26, 2025 by Benjamin Brumm

The automotive supply industry is undergoing enormous change, driven primarily by the technological shift towards...

May 26, 2025 by Benjamin Brumm

The automation of manufacturing processes - whether in series production or small series production - is one of the key...

Can we help you with your questions about automation? Would you like to know how you too can implement a project quickly and user-friendly in your company?

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de