3 min read

Motek 2023: AI-powered robots and new Solution Kit machine tending

Sylvie Rest

:

Sep 6, 2023 3:29:00 PM

Sylvie Rest

:

Sep 6, 2023 3:29:00 PM

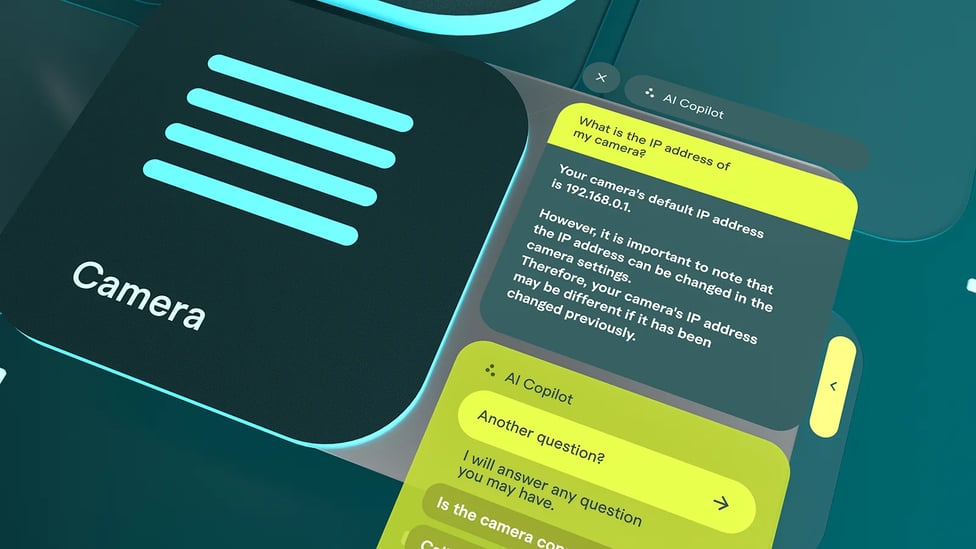

At the end of June at Automatica 2023, fruitcore robotics had unveiled its new operating system with integrated AI Copilot for HORST industrial robots, making a statement for the future of industrial automation. The Digital Robots from the pioneer of intelligent robotics and automation solutions are the first, that can be set up and controlled with ChatGPT support. Here, the voice model acts as an intelligent assistant that answers questions and provides assistance in natural language and in real time. At the upcoming Motek 2023, fruitcore robotics will present its AI innovation. Also to be discovered are the Solution Kits, automation modules for production scenarios such as machine tending or parts separation.

"Artificial intelligence is making a significant contribution to more agile and flexible automation and will undoubtedly fundamentally change the automation landscape. We are proud to have pioneered the first GPT integration in industrial robotics," says Patrick Heimburger, Managing Director (CRO) of fruitcore robotics. Especially in complex automation processes, the AI-powered industrial robot proves to be extremely helpful – for robot experts as well as for beginners. The AI Copilot not only facilitates the integration and control of robots and components, the innovation also has a positive impact on efficiency and time savings. This is a valuable contribution to increasing profitability, explains Heimburger.

AI Copilot: real-time help assistant for HORST industrial robots

Under the AI Copilot, fruitcore robotics bundles a variety of AI-powered functions in the central control software. These functions will be available to users in the future when it comes to setting up and controlling HORST industrial robots as well as entire applications. The AI Copilot answers questions in real time and in natural language, making support calls a thing of the past in many cases. For example, if the user wants to know how to transfer the part position detected by the camera to the robot, he can address this question to the AI Copilot via text prompt and receive the corresponding code module within a few moments. The AI Copilot can not only generate functions, program blocks and program templates, but also optimize and correct programs and even detect possible errors at an early stage. Thanks to correction suggestions, these errors can then be quickly corrected. Finally, the AI Copilot also acts as a kind of personal trainer and sparring partner, even providing support for professional development.

The AI Copilot developed by fruitcore robotics on the basis of ChatGPT was trained with relevant assembly instructions, support content and software documentation from the Constance-based company. To guarantee users an outstanding user experience, the capabilities of the intelligent assistant are continuously being expanded. At Motek 2023, trade visitors can experience fruitcore robotics' AI Copilot live and try it out for themselves at booth 7209 in hall 7.

HORST Solution Kits: automation modules that can be integrated quickly and flexibly

In addition to the AI innovation, two other actors will be spotlighted at the fruitcore robotics booth: the Solution Kit Part Separation, a CE-certified automation module for flexible parts separation of bulk materials, and the latest Solution Kit Machine Tending, a CE-certified automation module for machine tending. The latter is based on HORST1000, the latest member of the HORST robot family. The industrial robot scores with a payload of up to 8 kilograms, a reach of 1018 millimeters and a three-dimensional workspace, making it ideal for loading and unloading any machine tools. All Solution Kits from fruitcore robotics are tailored to specific production scenarios of industrial companies and equipped with all components required for the respective application. The integration and control of robots, components and existing industrial processes is carried out via the interface of the new operating system horstOS as a single point of contact, through which users can centrally manage all components integrated in the overall system, such as grippers, camera systems and safety systems. The AI Copilot assistance function also contributes to a significant simplification of human-robot interaction here.

"Our Digital Robots and Solution Kits are geared towards cost-effectiveness, flexibility and efficiency in all their life phases, the cornerstones of modern manufacturing," says Jens Riegger, Managing Director (CEO) of fruitcore robotics. "This focus enables industrial companies to start their automation projects with minimal implementation effort and achieve a rapid return on investment", said Riegger.