horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

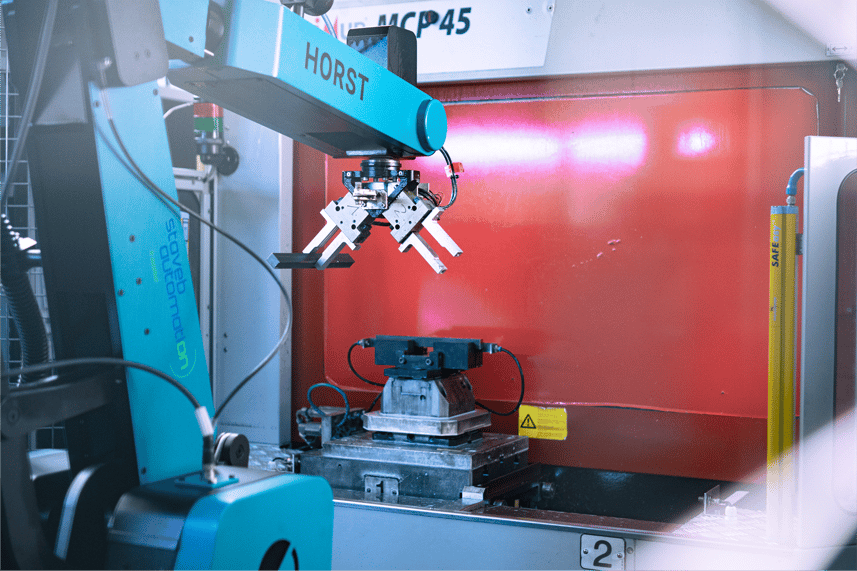

Increased efficiency thanks to automated loading and unloading of a milling machine

CyFa-Tech.ch Manufacturing Solutions, a Swiss company based in Wiedlisbach, specializes in CNC turning, milling and measuring, primarily for the hydraulics industry. Its services include, for example, the production of hydraulic valve blocks and guides for linear systems. Components for drive spindles for milling machines and parts for the automation industry are also part of the portfolio of the team from Oberaargau. A Famup MCP-45 machine with two pallets is used to mill the parts in the case described.

Area of application: Machine loading & unloading

Industry: Metal processing

Company size: Small company (6 employees)

Series size: 10-50,000 parts

Robot amortization time: 3 months

Milling parts on the CNC machine at CyFa-Tech.ch Manufacturing Solutions was characterized by a monotonous and capacity-binding way of working. This monotony was stressful for employees and costing the company a lot of money. The aim was to automate the loading and unloading process of the CNC milling machine.

Process reliability: Parts must be picked up and set down reliably and consistently

Repetition accuracy: Parts must always be positioned in exactly the same place

No errors: No technical faults may occur during loading and unloading

Efficiency: Ideally, operation should be possible 24 hours a day, seven days a week, including ghost shifts

With the support of Staveb Automation AG, a certified system partner of fruitcore robotics, the loading and unloading process was fully automated. Only the raw material has to be replenished by the employees.

"With HORST, we have achieved a huge increase in efficiency. We now produce twice as many parts and have been able to significantly increase our turnover. The robot paid for itself after just three months, or after the first series of 16,000 parts."

Fabian Pfister

Managing Director and founder of CyFa-Tech.ch Manufacturing Solutions GmbH