3 min read

What tasks do industrial robots perform in medical technology?

Johannes Füssl

:

Feb 5, 2025 10:43:11 AM

Johannes Füssl

:

Feb 5, 2025 10:43:11 AM

Automation is rapidly gaining importance in the manufacture of medical instruments and devices. All the more so because the current gradual introduction of mandatory labeling for medical products is increasing the amount of work involved in production. Precisely working industrial robots, which are also easy to integrate and operate, ensure implementation and also ensure the highest product quality.

These smart robots are already supporting numerous companies today: They load and unload machines, for example for unique product identification (UDI) by laser. Robots are also increasingly being used for classic pick-and-place tasks or in quality inspection.

Advantages of robots in medical technology

In few industries are quality standards as high as in medical technology production. And rightly so - after all, health is at stake. The careful handling of medical and surgical products demands an enormous amount of concentration from employees. And this at high cycle rates, even though they are handling sometimes hazardous substances or objects. Innovative robots make a valuable contribution to relieving the strain on humans so that production errors are avoided - and at enormous production speeds.

While assistance robots for operations or in rehabilitation - for economic and ethical reasons - will only become a widespread option in the coming years, industrial robots have long since arrived in medical technology. One of the strengths of modern robots is their flexible handling of a wide variety of parts: They move, sort, palletize and inspect workpieces reliably, quickly and safely.

The advantage of modern automation solutions: They are usually ready for use within a day, requiring neither extensive training nor in-depth programming knowledge. Robots can be operated almost as easily as a tablet or smartphone thanks to intuitive robot operating systems. The integration of artificial intelligence and the use of program wizards mean that no coding is required at all.

The advantage of modern automation solutions: They are usually ready for use within a day, requiring neither extensive training nor in-depth programming knowledge. Robots can be operated almost as easily as a tablet or smartphone thanks to intuitive robot operating systems. The integration of artificial intelligence and the use of program wizards mean that no coding is required at all.

A particular benefit for medical technology: Industrial robots can easily handle alloys and combinations of different materials that are typical for the industry. They are also insensitive to dust or dirt and are also suitable for production in clean rooms.

How robots are growing the medical technology sector

German medical technology is booming. According to the industry association BVMed, companies in Germany - as of November 2024 - generate a total turnover of 55 billion euros. They employ more than 200,000 people. Despite widespread economic problems, medical technology remains on course for growth, with annual growth rates of around five percent.

93 percent of medical technology companies are SMEs, have fewer than 250 employees and in some cases still have small batch sizes. The industry association calls these SMEs the “heart of the industry and drivers of progress in medical technology”.1 Flexibility and rapid retooling and part changes are particularly important for these companies, and this is exactly what today's automation solutions make possible.

Easier implementation of the labeling obligation thanks to robots

The demands on quality, reliability and reproducibility in medical technology have increased once again since 2017 at the latest. Internationally applicable guidelines for the labeling of medical products pose new challenges for the industry.

At that time, an EU regulation came into force (MDR), according to which medical products must be individually identifiable. There is also a labeling requirement in the USA, which is based on the European regulation.

These regulations are also an opportunity for German medical and laboratory technology companies and their service providers. This is because they can present themselves as particularly reliable vis-à-vis global competitors. The UDI system (Unique Device Identification) requires each part to be marked with a serial number and a code. Robots help to implement these international specifications quickly, safely and easily when manufacturing products.

Use of robots in laser marking

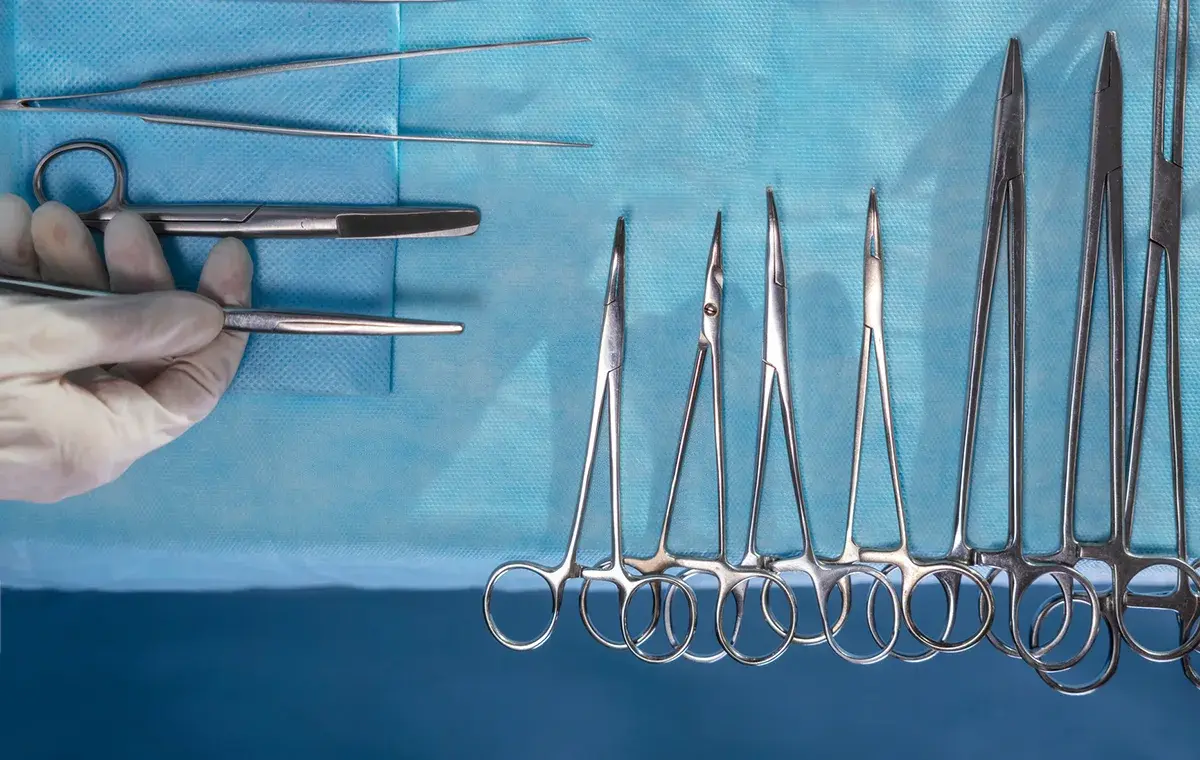

Scalpels, drills, surgical forceps and other medical products are usually marked by laser. If medtech manufacturers want to have this done automatically, they should look for a robot that works as repeatably as possible: ± 0.05 millimetres, for example, is a very good value for achieving precise results even at high speeds.

Precise and flexible robot systems therefore increase productivity in labeling without exploding costs. In most cases, the investment in automation pays for itself in less than six months. Another important aspect is that robots do not become ill and do not require vacation. In the event of short-term or permanent staff shortages, production can still be maintained and there are no delivery problems.

Precise and flexible robot systems therefore increase productivity in labeling without exploding costs. In most cases, the investment in automation pays for itself in less than six months. Another important aspect is that robots do not become ill and do not require vacation. In the event of short-term or permanent staff shortages, production can still be maintained and there are no delivery problems.

Holistic automation as an immediate solution for medical technology

Automation becomes even easier for medical technology companies if they use pre-prepared and CE-certified complete modules, which are available on the market for numerous applications from machine loading to parts handling and separation. In addition to the robot itself, they already include all the necessary tools, accessories and safety technology.

For a long time, these flexible, modular solutions - for example for laser marking in a cell - were not available on the market. Conventional complete solutions often did not meet all users' needs. Interested parties could then either fall back on the classic pick-and-place solution, i.e. have the marking device loaded by a robot standing in front of it. Or they had to do without application areas - in the case of laser marking, for example, 360-degree marking or switching between different components. A lot of money and planning effort also often had to be invested in protective enclosures.

Sources:

1 https://www.bvmed.de/branche/zahlen-und-fakten#3-medtech-markt-auf-einen-blick