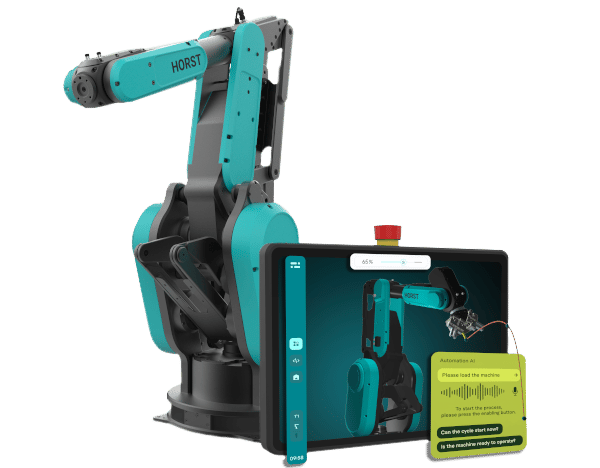

horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

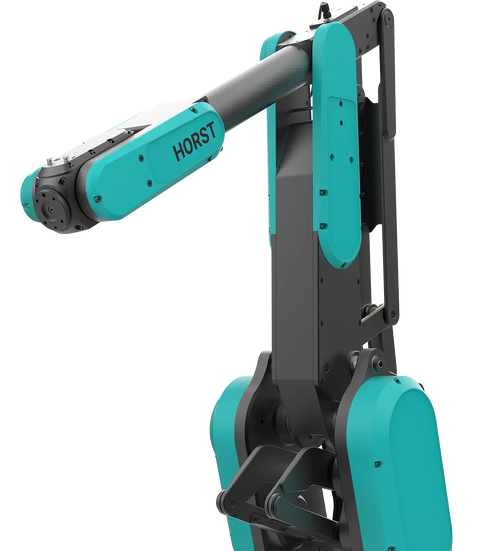

HORST1500 G2 stands for maximum efficiency in automated production.

With its compact design, long reach and optimally utilised working space, it is the ideal solution for the efficient loading and unloading of machine tools – with minimal setup effort and an ROI of less than 6 months.

Technical data that impresses: performance values, precision, and robustness that you can rely on in industrial applications.

You receive a robot, controller, panel, and software that are perfectly coordinated, ready for immediate use, and 100% made in Germany.

Download detailed information about the Digital Robot HORST1500 G2

Configure your HORST1500 G2 to meet your specific requirements.

Select components, accessories, software packages, and interfaces, and immediately receive a transparent overview of your customized configuration.

Simple. Fast. Transparent. This is how you design your automation with HORST.

Configure your offer

Discover the entire HORST family – from compact models for confined workspaces to powerful variants for long ranges and high load capacities.

You will find the right HORST for every application.

Reichweite

1485mm

Traglast

15 kg

Wiederholgenauigkeit

+/- 0,05 mm

Gewicht

110 kg

The HORST1500 G2 is designed for demanding automation tasks in machine tool loading.

Its machine learning-optimized kinematics ensure the shortest cycle times and maximum productivity, while its robust design allows it to work reliably even in harsh environments.

Learn more about the suitable applications and discover how HORST1500 G2 can help increase your productivity.

Would you like to know how you can use HORST1500 G2 in your production?

Our robotics experts will assist you with questions regarding the feasibility, planning, and setup of your application—personally, practically, and on equal terms.

Together, we will find the right solution for your automation.