horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

3 min read

Patrick Heimburger

:

Aug 11, 2025 5:34:55 PM

Patrick Heimburger

:

Aug 11, 2025 5:34:55 PM

Constance/Düsseldorf, August 11, 2025 - fruitcore robotics and EDM specialist Sodick have entered into a strategic partnership for the automation of precision machines. The customized robotic solutions from fruitcore will initially be used on the two Sodick machines AD35L and ALC600G for die-sinking and wire erosion. Thanks to the collaboration, modular automation solutions are available that can be quickly set up, easily operated and flexibly adapted to existing production processes.

Monday morning, 6:45 a.m., in the production hall of a precision company: the production manager looks frustratedly at the idle machine. Yet another delay because there are no employees and the automation he has been waiting for is too complex. Thousands of manufacturing companies are familiar with this scenario, in which machine downtimes have a massive impact on efficiency. The collaboration between Sodick Germany and fruitcore robotics ensures a more relaxed start to the week.

"Our customers attach great importance to high productivity and utilization of our machines. After all, this involves high investment costs and corresponding amortization targets," explains Giuseppe Addelia, Managing Director of Sodick Germany. "Production delays and downtime lead to high costs. It takes far too long to get an automation solution up and running in productive operation. It needs to be simpler and faster."

According to industry analyses, manufacturing companies often spend several months to a year integrating new automation solutions - a costly wait that can now be avoided.

Addelia also emphasizes that automation should complement existing processes and not replace them: "The systems can be operated manually, partially automated or completely unmanned and therefore support a wide variety of manufacturing strategies."

This is where the strategic partnership between Sodick and fruitcore comes in: The modular robot solutions (Robotic Solutions) from the robotics company from Constance have been specially developed to reduce integration times from several months to just a few days. Among other things, this is made possible by the intuitive software, which has been highly regarded by users for years.

The simple programming and configuration of the software and control system, as well as the high degree of flexibility for customized solutions according to the requirements of the Düsseldorf erosion specialist, were decisive factors in bringing about the cooperation. Sodick also expressly emphasizes the speed of response and solution-oriented cooperation with the fruitcore application technology team.

"Speed and high quality are crucial for success when communicating with customers and partners," explains Patrick Heimburger, Managing Director of fruitcore robotics. "In addition to the software and hardware benefits of our products, this is an important factor for machine and plant manufacturers when it comes to significantly reducing the implementation effort and time-to-market of the finished system." In Sodick's case, a few months passed between the first inquiry and series production.

Sodick and fruitcore robotics are now presenting two specific solutions that effectively address the challenges of modern production for the first time at EMO, the world's leading trade fair for production technology:

- AD35L with SDG.HR50-6 axis robot A compact and robust die-sinking EDM system, optimized for fast and precise part handling.

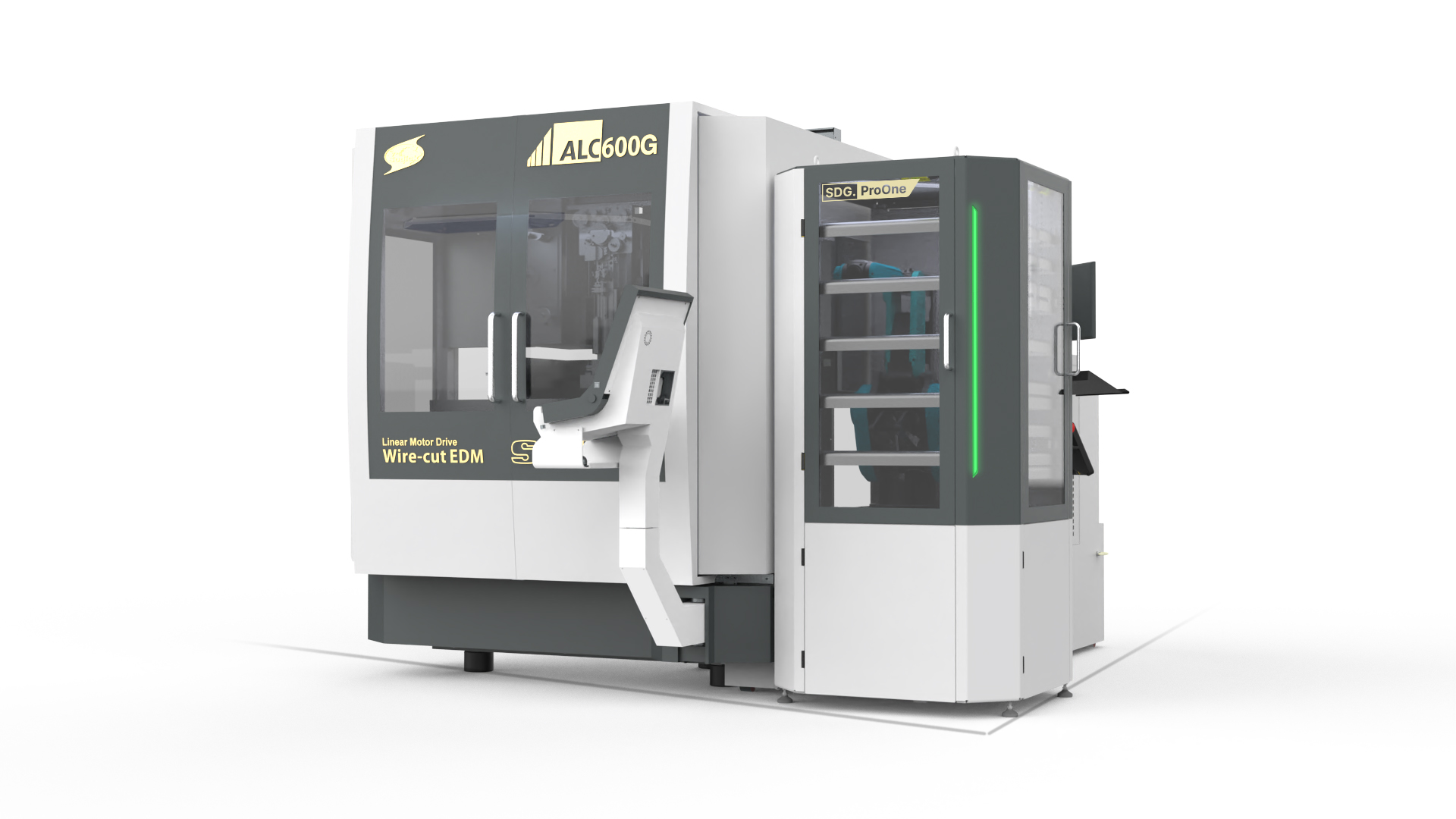

- ALC600G with SDG.ProOne 6-axis robot An innovative automation solution for wire EDM, specially designed for improved surface quality and - thanks to patented wire rotation - reduced material consumption.

The robotic solutions from fruitcore robotics are based on modular hardware and the AI-supported software horstOS. Machine and plant manufacturers and their customers benefit in several ways:

- Fast commissioning: robot solutions can be used productively within a very short time

- Intuitive operation: horstOS software enables simple programming and quick configuration - no PLC programming required

- Flexible and scalable: hardware and software have a modular design and can be individually adapted to different machines and processes

- White label options: Software and control system can be seamlessly integrated into existing control systems or individually branded

- Efficient processes: Significant time and cost savings can be made by using standardized, customizable solutions.

"As an automation partner for machine and plant manufacturers, we enable Sodick to quickly and easily integrate high-performance, customized automation solutions into their product portfolio. The combination of our robotics know-how and Sodick's expertise as a machine specialist creates tangible added value for end customers."

Patrick Heimburger, Co-Founder and Managing Director of fruitcore robotics

"Our customers expect solutions that can be smoothly integrated into existing processes. fruitcore robotics impresses us with its modular robot cells, outstanding software and dedicated support. This enables us to offer high-quality and cost-effective complete solutions that are suitable for loading CNC machines, for example."

Giuseppe Addelia, Managing Director Sodick Germany

*****

- Strategic partnership: Individually adaptable robotic solutions from fruitcore robotics integrated at Sodick Germany

- Solutions: AD35L with SDG.HR50 robot cell (die-sinking EDM), ALC600G with SDG.ProOne (wire EDM)

- Advantages: simple operation of the entire process (horstOS software), individual support for machine and system manufacturers, fast integration and project implementation

- Customer benefits: Simple programming, high flexibility, short time-to-market

- Public premiere: EMO 2025 in Hanover, hall 12/booth C59 (22.-26.09.2025)

The ALC600G wire EDM machine with SDG.ProOne, optimized for fast and precise handling. Image: fruitcore robotics.

Giuseppe Addelia, Managing Director Sodick Germany. Picture: Sodick Deutschland GmbH