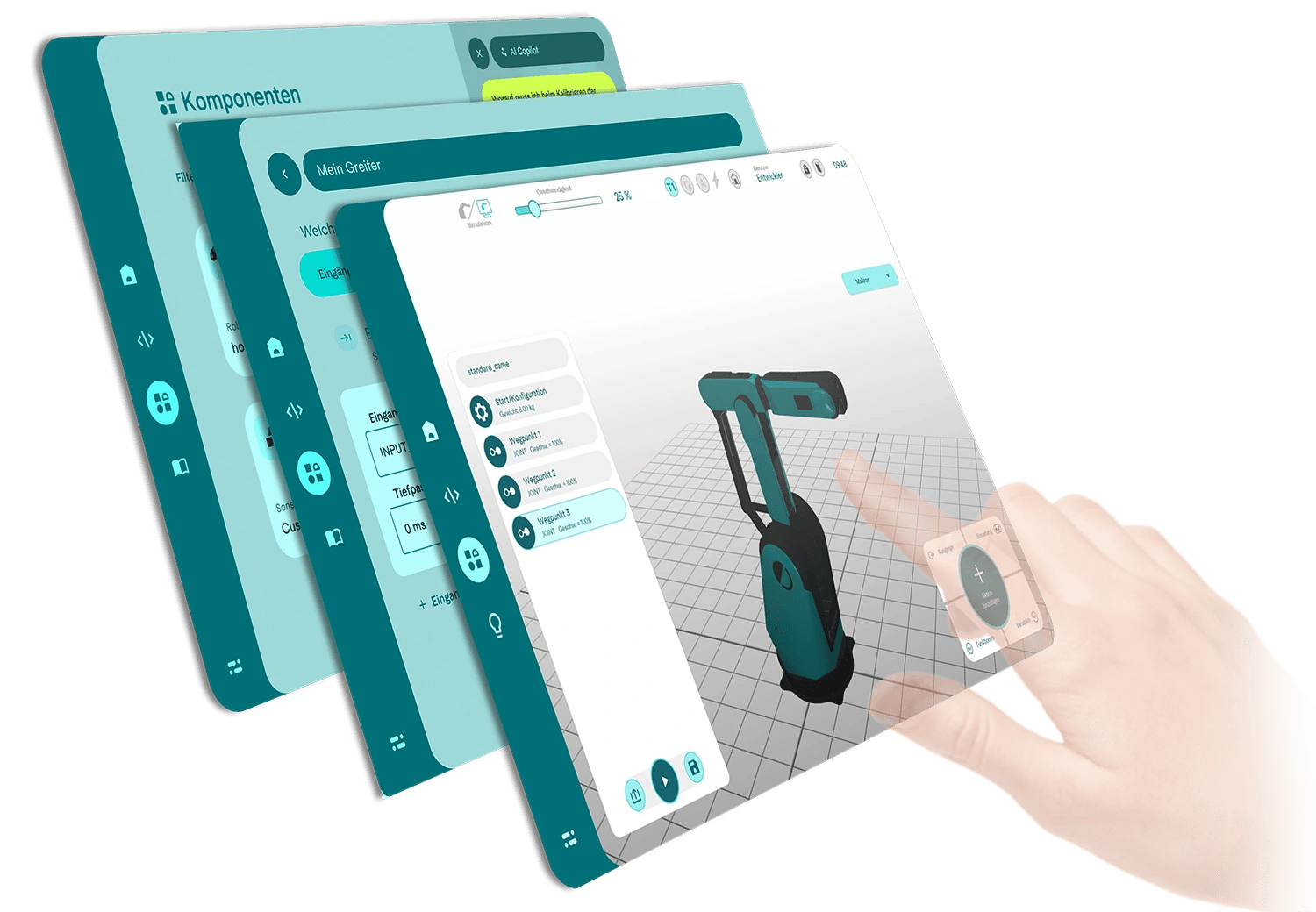

Maximum flexibility through

holistic software

Experience horstOS and horstFX

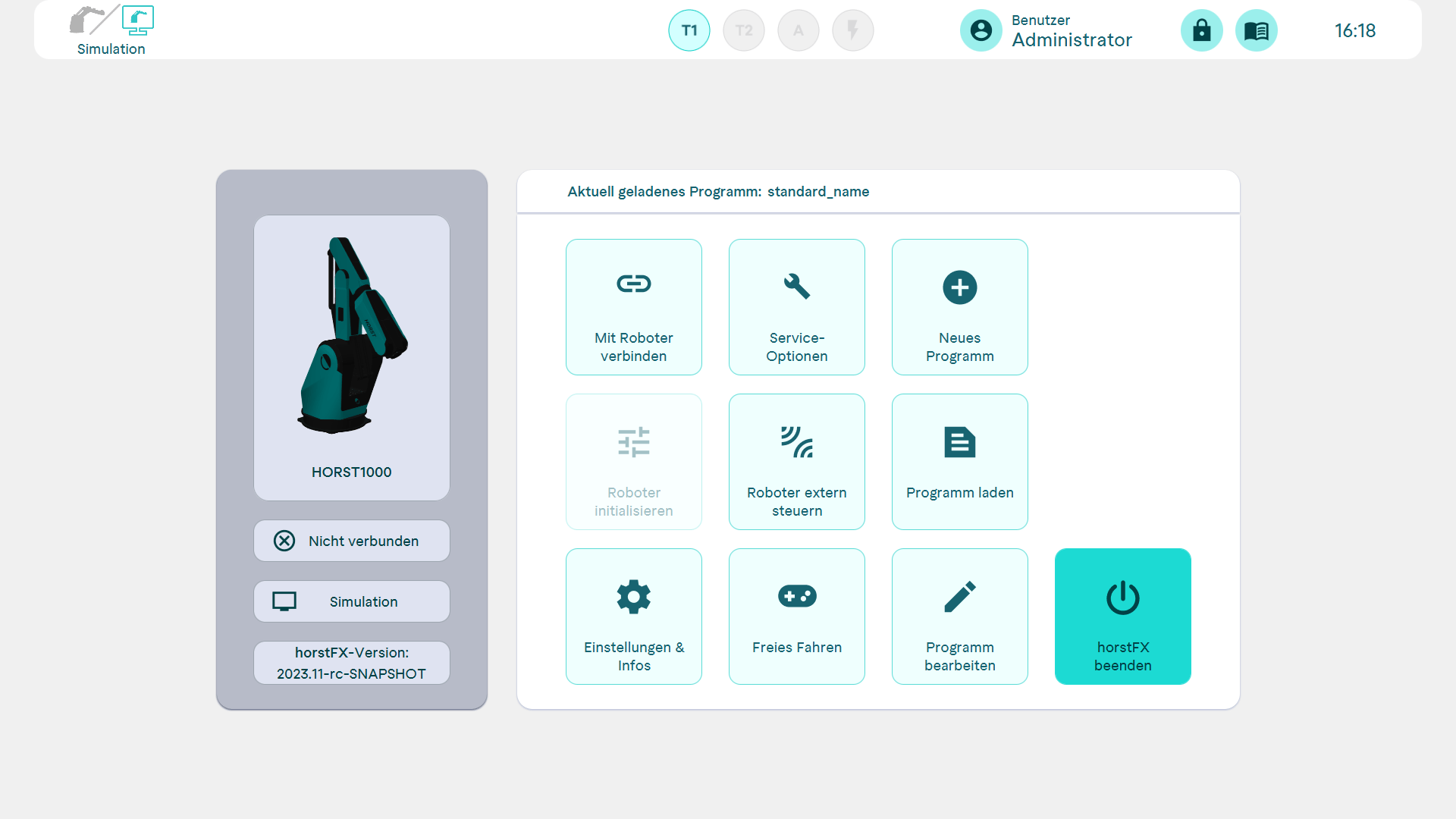

Imagine if your automation system was not only powerful, but also extremely easy to operate. Our horstOS central control software enables this - effortless component setup, intuitive programming with horstFX, flexible system control.

The components of our central control software horstOS: robot programming is just the beginning

Transform your automation into a versatile and user-friendly solution with the Digital Robot central control software - your key to easy automation. Our software makes it easy to set up components, program individual processes intuitively and control the entire system flexibly. Flexible, simple and customizable - benefit from numerous advantages with horstOS:

Program generation with horstFX

- Switch seamlessly between graphical and textual programming

- Expressive simulations and feasibility analyses in 3D

Programming with horstFX gets the best out of the software for both beginners and experts. Create simple programs graphically in 15 minutes using a digital twin and a 3D world. As an experienced user, you can fall back on textual programming.

Project Setup

- Centralized setup and management of all system components

- Vendor-independent integration of software and web tools

Easily add components and manage them using predefined standards and the auto-complete function. Existing software can be seamlessly implemented in horstOS, regardless of the vendor.

Process control

- Access to all components via single point of control

- Flexible interface according to process and operator requirements

Access all components involved in the process intuitively via a single point of control. Use the most efficient control and avoid errors thanks to personalized user interfaces.

AI Copilot

- Real-time support without delays

- Early error detection and quick resolution

Get help from the best, context-sensitive support in real time. Program more efficiently with AI optimization of programs and AI-supported creation of program modules and functions.

Description text for the video above.. Sed quam suspendisse in vulputate vitae arcu. Volutpat suspendisse mi turpis elit nec. Amet sem id nulla amet nisl. Nulla a adipiscing porta elementum in nunc eleifend vitae. Placerat fringilla ultrices rhoncus risus. Iaculis at facilisi et pellentesque amet nunc. Enim nunc varius fringilla odio pellentesque.

IIOT platform horstCOSMOS: For even more process reliability

Take advantage of the IOT connectivity of our products: Program backups, over-the-air updates, predictive maintenance and much more.

1

High process reliability

Maximize availability with predictive maintenance. Regular program backups for additional security.

2

Fast responsiveness

Always keep an eye on your request via the online service system. Handle many service cases via remote support.

3

More transparency

Maintain a simple and transparent overview of your robot fleet and booked services.

4

Central knowledge base

3D models, instructions, application examples and much more: all the information you need about your HORST.

Learn more about our Digital Robots

What our satisfied customers say about the Digital Robot HORST

We use the test cell for technological feasibility analyses and innovations in product development and are thrilled. The Solution Kit can be put into operation, programmed and operated quickly and easily without any special prior knowledge.

With HORST, we are very well positioned in our test lab. The compact footprint is very convenient and the usability of the robot is a great advantage, especially for the complex test setups.

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

The high quality demands placed on our products require first-class quality assurance. By using the HORST industrial robot, we have not only created the best testing conditions, but also significantly increased product quality. The robot has relieved our employees of monotonous tasks as well as led to an increase in productivity and a high level of satisfaction among our customers.

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

HORST takes over typical pick & place tasks for us during a hydraulic test and enables a fully automated testing process. As a result, we achieve a significantly higher output and increase our productivity. We were also convinced by the easy operation of the industrial robot, the good price and the comprehensive support from fruitcore.

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.