Today, industrial companies are faced with more challenges than ever before. If they want to remain successful in the long term and survive in the competitive market, they must respond appropriately to growing cost pressure, a severe shortage of skilled workers, or digitization, for example.

These and other factors will mean the difference between success and failure in the future. Learn more about the key challenges facing the industry here.

1. Cost Reduction

Companies must constantly look for ways to reduce their costs in order to remain profitable and increase their profit margins. This can be achieved, for example, by introducing more efficient production processes or using automation. Costs can also be reduced by minimizing waste and using materials and resources efficiently.

If costs fall at the margins of manufacturing operations, products can be offered at correspondingly low prices without sacrificing quality.

Companies that are unable to do this are likely to have difficulty competing in the near future. Conversely, lower costs help to retain customers and free up companies to invest in new technology, such as automation.

2. Cushioning the Skills Shortage

There is a shortage of personnel in almost all sectors of the economy, and there is a massive shortage of qualified specialists in particular. Industry in particular is affected by a lack of personnel for several reasons, although the causes can vary depending on the region or industry. In highly developed industries such as Germany, for example, demographic change, an education system that has been geared toward academization for years, or a declining attractiveness of physically demanding or monotonous jobs are making themselves felt.

The manufacturing sector can respond to this with a variety of measures. Among other things, companies can provide targeted training and development for existing staff in order to bring missing know-how in-house. Secondly, it helps to keep the general conditions of the job as attractive as possible, for example by offering appropriate salaries, flexible working hours and a modern corporate culture. Another lever is new ways of recruiting (e.g., via social media or job fairs). Looking abroad also helps some companies to find suitable personnel. Here, politicians are called upon to create the appropriate legal framework.

One instrument against the skills shortage that should not be underestimated is automation. Working with industrial robots, for example, can relieve workers, free them from unattractive tasks and increase efficiency. In turn, employees can devote the newly gained working time to new activities in the company for which human creativity remains irreplaceable.

3. Increase Productivity

Thanks to new technologies, process optimization and an improved network of departments, companies can increase their productivity and thus strengthen their competitiveness.

Regularly putting workflows and processes to the test avoids waste and inefficiency. Open communication, especially when accompanying employees into a technologized and digitized working world, ensures motivated and committed personnel. Company management should take this into account and specifically promote further training in the use of new technologies.

Industrial companies should also - if they do not want to lose out to global competitors - address the possibilities of modern technologies at an early stage. This applies regardless of the size of the company; the introduction of artificial intelligence, machine learning and robot-based automation are not reserved for large corporations and are certainly no longer utopian. Rather, they promise to enable companies to optimize their workflows, increase efficiency and reduce human error.

4. Create a safe and modern working environment

A safe and modern working environment helps to increase employee satisfaction and retention. It can also increase productivity because employees can work more efficiently.

Satisfied workers naturally want a low-risk and balanced job. It has a positive effect on the retention of existing staff, and especially on the search for new skilled workers, if a company presents itself as attractive, future-oriented and open to new technologies and processes.

Modern machines and robots, along with sustainable business practices, diversity, equality and fair communication, are important factors for a positive image of companies in Industry 4.0, not least because automation frees skilled workers from monotonous or even risky tasks and allows them to devote themselves to more varied tasks.

5. Ensure Competitiveness and Future Viability

Companies must constantly adapt to changing, sometimes unpredictable market conditions. This flexibility is the basis for remaining innovative and competitive. Investments in research and development, new business models or technologies demonstrably promote long-term economic assertion on the market.

In order to arm oneself against the competition, it is therefore important to target the measures described above. They are all aimed at competitiveness and future viability. It is obvious: companies that attract qualified employees and offer them a pleasant working environment can reduce their costs and increase their productivity. As a result, they gain a strong position in the market and are better equipped to deal with crises. The past few years have shown how important this has become for economic success and is likely to remain so in the future.

6. Drive Digitization forward

Digitization has now progressed so far that basically all companies, from one-person operations to large corporations, can use it for their own purposes. By introducing digital technologies, automation or the targeted handling of data, companies can increase their efficiency, quality and sustainability.

According to a study by industry association Bitkom, Industry 4.0 is changing entire business models in three out of four German industrial companies, not just individual workflows or processes. 55 percent of the companies surveyed emphasized that Industry 4.0 is generally giving their own business a new boost. Digitization is seen as an essential factor in maintaining competitiveness in the industrial world of the future.

Digitization in industry encompasses diverse technologies, strategies and processes. Above all, the term Industry 4.0 is used to describe the fourth industrial revolution, the main features of which are cyber-physical systems (e.g. smart factory), the Industrial Internet of Things (IIoT) or cloud computing. Some are now already talking about the more advanced Industry 5.0.

IIoT means the networking of devices, machines and sensors to collect, exchange and analyze data. Companies can thus optimize their production processes and efficiency. Thanks to cloud computing, companies can access applications via the Internet that require enormous computing power. This allows them to scale their own IT infrastructure and reduce costs for high-performance computers, for example.

The advance of artificial intelligence (AI) and machine learning means that patterns can be identified ever more clearly from the data collected. This can help to further optimize products or minimize machine downtime (e.g. due to incorrect or untargeted use).

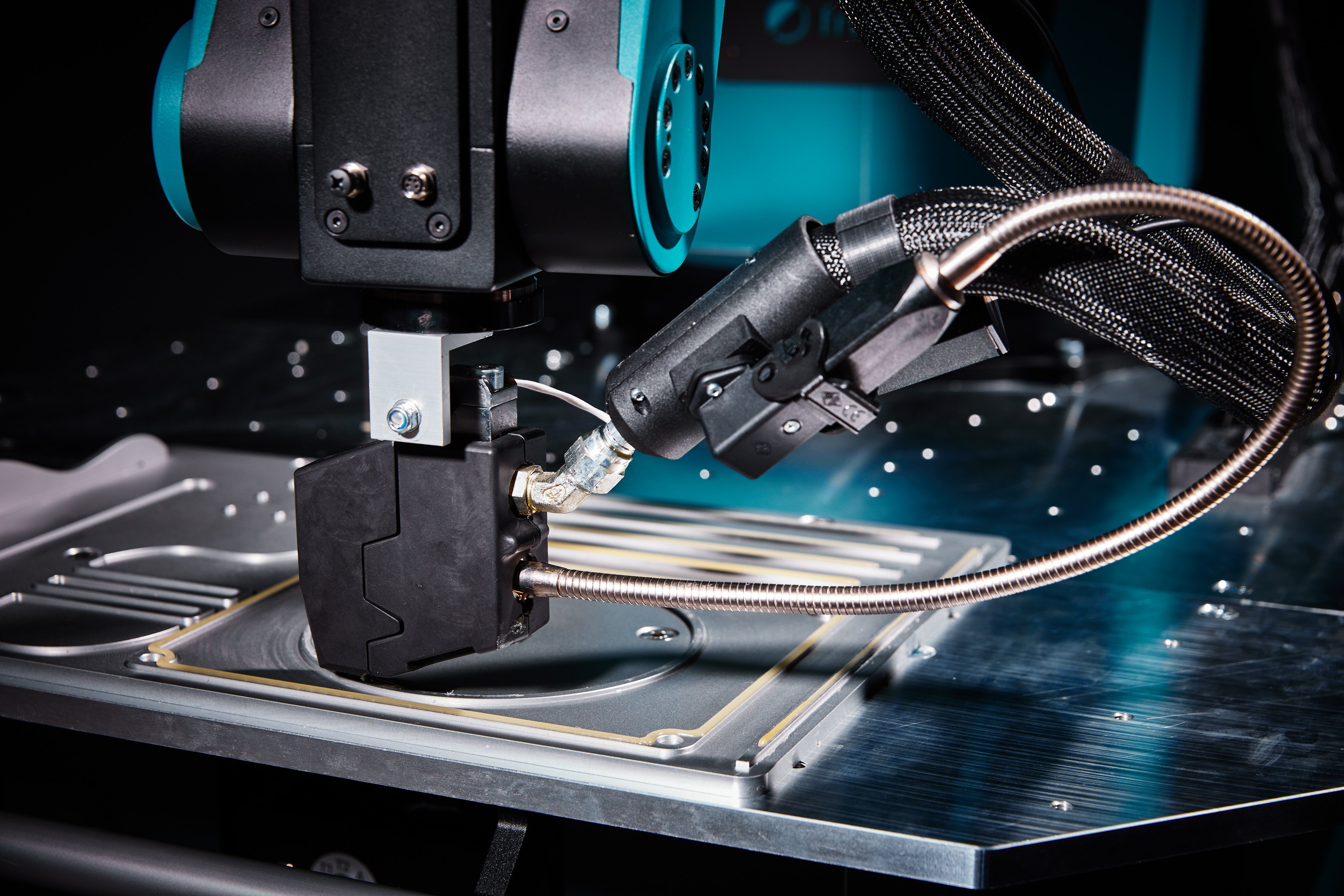

Many production companies are just starting on the road to automation and are using industrial robots for their tasks. It has been proven that this can increase efficiency, reduce errors and make production more flexible. Some robot and machine manufacturers are already working with the concept of digital twins to operate their products. These virtual images of the physical objects make it possible to simulate, analyze and optimize production processes.

7. Implement Automation

It is in the nature of things that automated production is faster and more efficient than manual production. After all, unlike humans, robots and machines can work around the clock and without breaks. Related to this, waste can be minimized because defective products (for example, from lack of concentration or inadequately trained personnel) are fewer. Automated systems work more accurately and with consistent quality across a wide range of applications.

While the investment in automation may seem high at first, it often pays off for companies after just one year due to high labor costs in high-wage countries. When monotonous or even risky tasks no longer have to be performed by humans, safety in the production hall increases and accidents can be avoided. Furthermore, the company positions itself as innovative in attracting new employees.

Thanks to further developments in automation, there is no need for a complete reorganization of production. Thanks to modern robots and machines, the first projects can be implemented in a short time. On the one hand, this helps newcomers to the subject, but also saves a lot of time for existing automation know-how and creates scope for transferring this know-how into the practice of almost any company.

8. Further Challenges

The points described above are only the most important challenges facing the industry. If companies address these, they are already on a very good path. However, there are other (mega)issues that should be taken into account. Think, for example, of globalization, of customers' demands for ever better, individualized but nevertheless inexpensive products, and of the increasing threat posed by cybercrime. Despite all the advantages of digitalized and networked production, companies should always pay attention to how their data is handled, where it is stored and that they retain control over it.

Other factors to be mentioned include increasing environmental and sustainability requirements as well as new or amended (internal) national guidelines and laws. Since the covid pandemic or new armed conflicts, also in Europe, supply chain management is once again coming under greater scrutiny. There is a shift back towards company headquarters in order not to have to interrupt production processes and to be able to deliver on time.

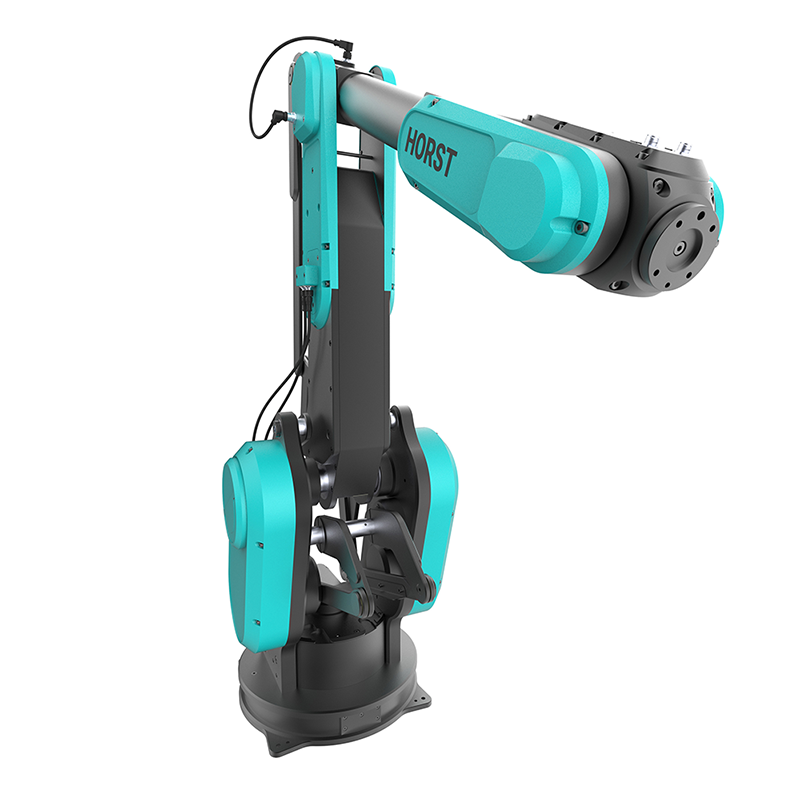

Discover the future of the industry - Intelligent robots for your company!

Our tip to successfully meet these challenges: Think about using a simple, flexible robot for the industry! We offer customized solutions that help reduce costs, increase productivity and provide a safer working environment.

Article

Article

Article

Article

Article

Article

Article

Article