horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

Learn more about the differences between industrial robots and cobots in manufacturing. Find out which type of robot is the best choice for your challenges!

Compare the benefits offered by industrial robots and cobots and check the advantages for your individual application.

| Intelligent industrial robots | Cobots | |

|---|---|---|

Service life |

Up to 100,000 hours in rated operation thanks to the use of durable planetary gearboxes |

Shaft gearboxes used last 25,000 to 50,000 hours in nominal operation. More susceptible to faults, e.g. due to built-in sensors |

Speed |

Higher speed (at least 4.3 m/s at the TCP), maximizes productivity and the company's results |

Mandatory reduced speed in collaborative use for the safety of persons, actual speed dependent on risk assessment |

Economic efficiency |

Rapid amortization after 3 to 6 months, low acquisition, operating and maintenance costs |

Longer amortization due to higher acquisition costs, higher costs over the entire service life (shorter service life, more susceptible to maintenance) |

Risk assessment |

Simple thanks to modular and protected robot platforms and other safety systems; external safety sensors (e.g. light barriers) enable risk-free collaboration |

Easier in collaborative operation due to sensors already installed; retrofit safety systems often required for industrial applications |

Precision |

Very precise thanks to measuring sensors on the final drive, no re-teaching due to wear |

Drive components designed less for precision than for flexibility and collaboration options |

Flexibility |

Automation modules for many applications allow quick switching between tasks |

High, as designed for various tasks |

In addition to collaboration, there are other levels of cooperation between humans and robots. The most common in industry are coexistence and cooperation (synchronized division of labor). Here, sensors detect whether someone is approaching the robot. If necessary, the robot reduces its speed. As with safety fences and barriers, this enables a higher level of performance than with collaboration.

In a fully automated system, robots or machines perform all tasks without humans. These systems are usually specialized and perform the same task repeatedly around the clock.

In this mode, humans and robots share the same physical space but do not interact directly with each other. Each carries out its own tasks independently of the other.

Humans and robots work in the same space and at the same time, but on different tasks. They can complement each other, but they do not work on the same task.

Here, humans and robots work hand in hand, often on the same task. Special, integrated sensors and software enable safe and low-risk collaboration.

We are making space in our warehouse and are offering HORST1400 at a reduced price for a short time.

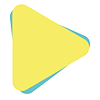

Do you want to load and unload distant machines or use heavy tools? Then you will be impressed by the reach and load capacity of this robot. Thanks to its innovative drive technology, it makes maximum use of its performance capabilities.

4 times longer service life, lower operating and maintenance costs than cobots.

No unnecessary sensors for cobot operation, no hidden costs during commissioning.

Significantly higher speeds than in cobot operation, which must be restricted by the Machinery Directive.

Completed risk assessment through modular and safe robot platforms; no hidden subsequent safety precautions.

Measuring sensors are located on the final drive, no reteaching necessary due to wear.

Find out more about the smart way of automation with intelligent industrial robots and for which tasks you can use HORST.

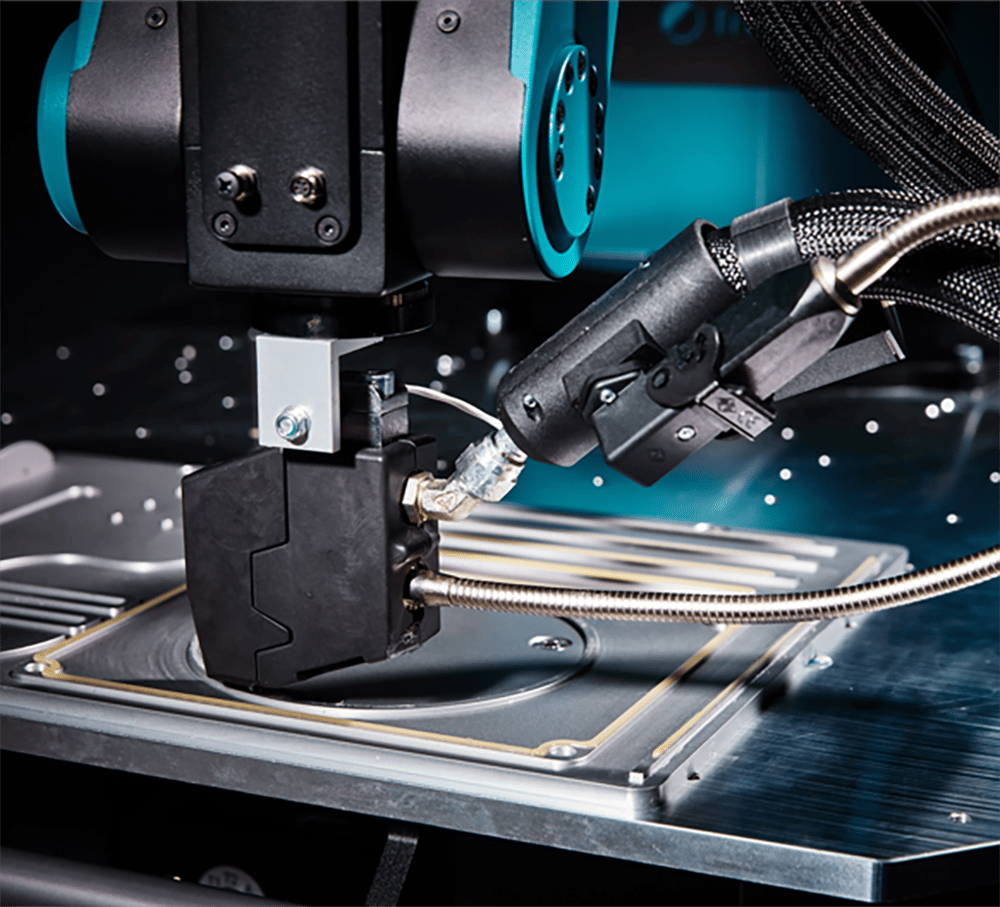

Cyfa-Tech, a Swiss manufacturer of complex milled parts, has achieved an enormous increase in efficiency with our smart industrial robot HORST1400: while the robot unmannedly loads a CNC machine, the employees can now devote themselves to other tasks. HORST1400 has already paid for itself after 3 months. This will not be the last project with a HORST for the up-and-coming specialist in the hydraulics industry!

Our robotics experts are always ready to talk to you about your specific needs. Let's talk about the best, most economical and sustainable solution for your company!

Firstly, the name HORST stands for being the friendly colleague in your company. HORST is a helper that relieves your employees of monotonous, dangerous or unhealthy tasks - it doesn't take their work away! At fruitcore robotics, we have deliberately opted for a catchy first name instead of a cryptic designation for our smart industrial robots, which also makes it clear that HORST stands for Made in Germany. HORST actually stands for Highly Optimized Robotic Systems Technology. This symbolizes how we at fruitcore robotics make powerful and complex deep-tech systems simple and accessible for you.

Industrial robots have been around for decades. However, our smart industrial robots no longer have much to do with these giant machines. HORST models are characterized by the fact that they are economically sustainable, intuitive to operate and program and easy to set up and integrate. They can also be used flexibly in almost all industries and for a wide range of applications - regardless of the size of the company or previous experience with automation.

First things first: HORST can work together with humans! There are different levels of collaboration between humans and robots. The most common stages in industrial practice are coexistence and synchronized division of labor. Sensors are used to detect the presence of humans in the vicinity of the robot and, if necessary, the speed of the robot is reduced to a standstill. This allows, for example, parts to be provided for the robot or transported to the next process step after processing by the robot. Just like the use of protective fences and grids, coexistence and synchronized division of labour enable high robot speeds. This leads to consistently high productivity and further increases in productivity - the primary goals when using industrial robots. The manual guidance of robots for programming paths is charming to look at and very playful - it works perfectly, especially in demo applications and for rough pre-programming. In industrial practice, the reduced maximum speed of cobots and other challenges, such as handling dangerous, pointed or sharp-edged workpieces, often speak against the use of cobots. This has led us at fruitcore robotics to develop smart industrial robots: programming is carried out for both simple and extensive programs using a sophisticated programming concept, graphical or textual programming. The safety controller can be easily connected to safety sensors such as laser scanners or light barriers. The monitored stop as well as speed and distance monitoring make it possible to work manually from an adjacent work area or alternate with automated operation. As a result, HORST smart industrial robots offer you simple operation combined with an attractive ROI.

Thanks to their innovative drive, our smart industrial robots have an exceptionally long service life and are also virtually maintenance-free. The key to a long robot service life lies in the type of gearbox. In practice, thanks to HORST's unique gearboxes, a service life of at least 50,000 hours can be assumed, even under high loads and with long operating times. This corresponds to more than five years! The shaft gearboxes usually installed in industrial robots last on average between 7500 and 10,000 hours at nominal load.

HORST is already used in hundreds of applications and areas of industry. It is used in the processing of metals or rubber and plastic goods as well as in mechanical engineering, medical technology and the electrical and electronics industry. Our smart industrial robots are not limited to specific sectors. Simply contact us and we will support you in your industry too.

Our smart industrial robots are designed for maximum flexibility - this also applies to the tasks you can tackle with HORST. Regardless of whether you want to automate your machine loading, parts separation, quality inspection or any other application: HORST will support you in such a way that the step towards automation becomes economical, sustainable and user-friendly for your company from A to Z. You can also use our intelligent industrial robots for the efficient and precise application of adhesives or dosing and let HORST support you in assembly. Find out more about the areas of application for our smart industrial robots in this overview.

You can purchase our smart industrial robots within Europe. Contact our sales experts for specific questions about purchasing a HORST from other countries outside the EU.

With HORST, you can forget long waiting times and delivery periods of up to 30 weeks (as with other manufacturers): With fruitcore robotics, it only takes a few days or weeks from ordering to the start of operation. We can deliver immediately, not least thanks to the Made-in-Germany principle! You can find out how we achieve this here.