horstOS is an end-to-end software platform that makes Physical AI usable for industrial automation – seamlessly connecting planning, implementation, and operation without media breaks.

SCHERDEL is one of the world's leading automotive suppliers. The family-run company produces a wide range of components from vehicle interiors to seat structures and powertrain parts. SCHERDEL products are installed in around 80% of all cars and commercial vehicles worldwide.

Areas of application: e.g. vehicle interiors, locking systems, drive train

Industry: Automotive

Company size: 6,800 employees

Locations: 35 locations and 45 manufacturing plants in 11 countries

Year founded: 1890

Website: www.scherdel.com

SCHERDEL wanted to have an existing stamped part inspected automatically. The challenge was that the product runs in very high quantities and both measuring and testing activities had to be automated. The company was looking for a flexible and simple solution without having to go down the route of a costly special solution.

No complex and expensive special solution, but simple and flexible to integrate.

Automation is intended to save personnel and therefore also costs.

We check the component, process and requirements directly on site

After a brief analysis, it is clear that automation is possible.

SCHERDEL places the order with us within one week.

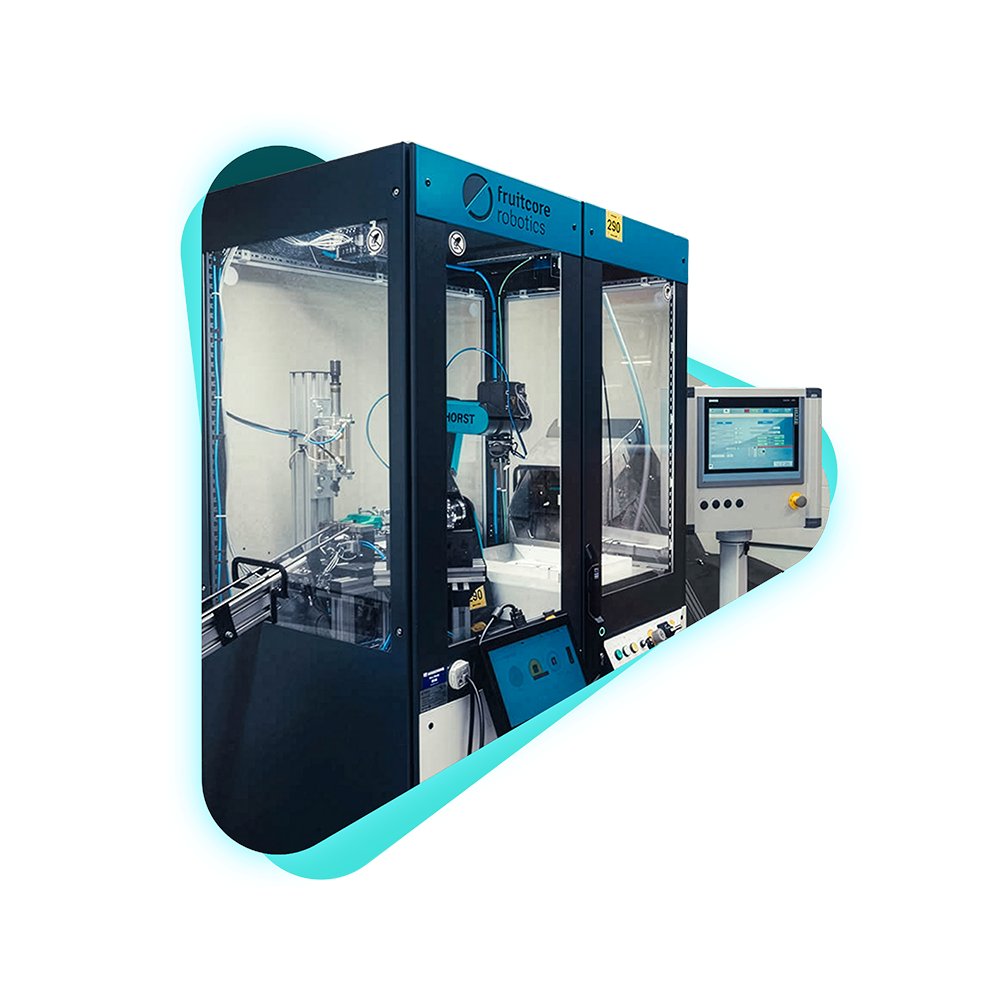

Just four weeks later, our Robotic Solution arrives ready to go

The automated system ensures consistently high quality and errors have been significantly reduced.

New parts & components can be integrated quickly & easily without external dependencies.

"Employee satisfaction has increased. A high degree of automation is also better for our customers. Fewer errors occur and we can integrate components into the systems more easily.

The support was great. fruitcore supported us from the feasibility analysis to ongoing operation."

Felix Nimtz

Process optimizer, SCHERDEL Marienberg GmbH