Article

Article

fruitcore robotics presents HORST1500, the new generation of its digital robots

fruitcore robotics, a pioneer in the field of AI-supported automation solutions, is expanding its...

With the new Solution Kit Part Separation with 2D Grasping-Kit, the partners fruitcore robotics and SCHUNK present an efficient and powerful solution for the fast and flexible automation of separation processes. The automation module sets a new standard for the vision-based separation of non-layered workpieces.

Geposted von:

Sylvie Rest

With the new Solution Kit Part Separation with 2D Grasping-Kit, the partners fruitcore robotics and SCHUNK present an efficient and powerful solution for the fast and flexible automation of separation processes. The automation module sets a new standard for the vision-based separation of non-layered workpieces.

The Solution Kits from fruitcore robotics offer industrial companies flexible and economical automation without a great deal of effort or training. Especially tailored to production scenarios such as machine tending and part separation, the automation modules contain all the components required for the respective application. The fully coordinated and validated Solution Kits ensure rapid project planning and implementation without the need for in-depth consideration of safety issues or extensive cost calculations.

For companies facing the challenge of handling unsorted parts in a box in an uncomplicated and flexible way, the Solution Kit Part Separation offers an optimal solution. The new variant with the SCHUNK 2D Grasping-Kit significantly strengthens fruitcore robotics' Solution Kit portfolio. It covers a wide range of components that can be processed within one configuration.

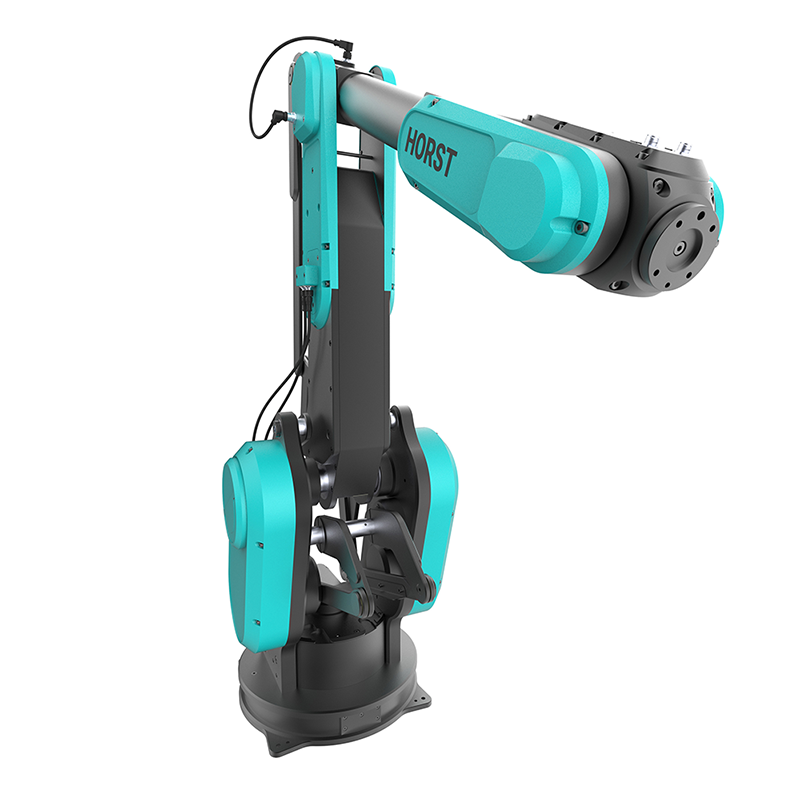

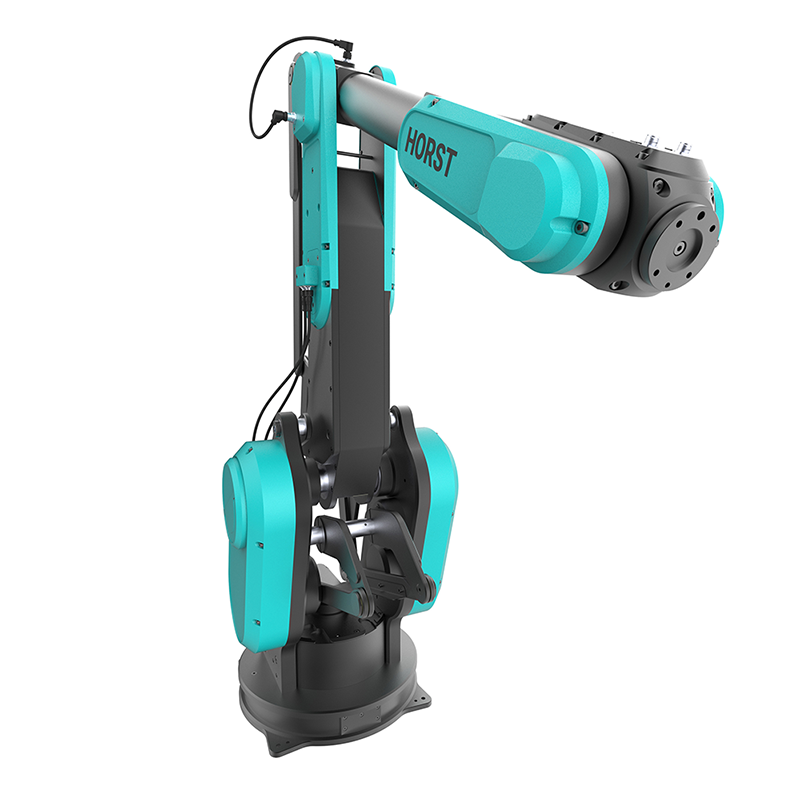

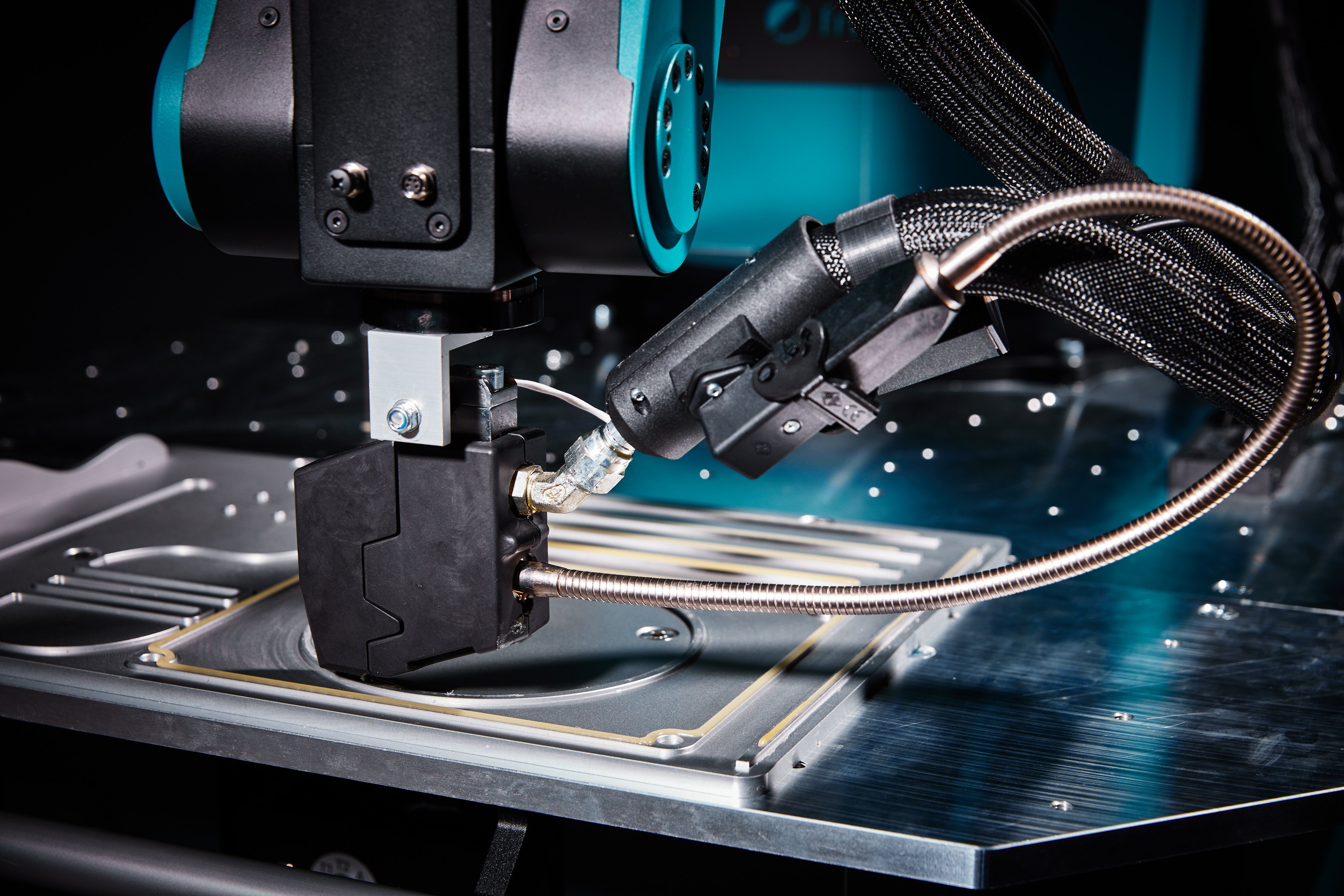

The Solution Kit Part Separation with 2D Grasping-Kit combines the AI-supported industrial robot HORST600, the 2D Grasping-Kit from SCHUNK including the mechatronic small parts gripper EGK and the part separator FlexiBowl and enables the vision-based automation of separation processes. These processes can be highly complex, especially when it comes to localizing different types of components or changing lighting conditions. The use of the 2D Grasping-Kit in the fruitcore robotics automation module simplifies the separation of parts, even with changing requirements. The integrated 2D Grasping-Kit comprises a camera system with lens, an industrial PC, the SCHUNK AI software and a plug-in for easy integration into the robot controller. It localizes different types of components and detects their position and orientation in order to grip and process them as required. For example, if the robot is to grip components with transparent outer packaging (e.g. screws and nuts in a plastic bag), the intelligent AI software from SCHUNK ensures reliable recognition of the components during the process.

Like all Solution Kits from fruitcore robotics, the Part Separation Solution Kit with 2D Grasping-Kit is characterized by its user-friendliness. Both experts and beginners can quickly commission and customize the automation module without in-depth specialist knowledge. This is made possible by preset parameters and the seamless integration of all components in horstOS, the AI-supported operating system from fruitcore robotics, horstOS, acts as a central control point through which users can intuitively manage the control of robots, components such as the 2D Grasping-Kit in the Solution Kit Part Separation and existing industrial processes. The AI Copilot assistance function makes operation much easier by providing contextual support.

Article

Article

fruitcore robotics, a pioneer in the field of AI-supported automation solutions, is expanding its...

Sylvie Rest

March 14, 2024

Article

Article

With the new Solution Kit Part Separation with 2D Grasping-Kit, the partners fruitcore robotics...

Sylvie Rest

February 20, 2024

Article

Article

fruitcore robotics is rolling out a new software update for its intelligent HORST industrial...

Sylvie Rest

November 15, 2023